Rare Earth Metals Are Essential In Modern Life But Production Is Unpofitable

By Rhod Mackenzie

The topic of rare earth metals has resurfaced again in connection with Greenland.

According to geologists, the melting of glaciers is causing the erosion of sand with particularly high concentrations of lanthanides from the underlying layers. It is therefore important to clarify why these elements of the periodic table are so appealing to the American president, and not only to him.

If experts had been asked in 1990 who the world leader in rare earth metal production was, the United States would have been the obvious answer. The USSR was, of course, the runner-up. Please could you explain how it came about that, thirty years later, China had become a near-monopoly?

Despite their name, rare earth metals (REMs) are actually quite common in the Earth's crust. Furthermore, humanity has accumulated a substantial amount of raw materials with the potential to be extracted. This includes iron and copper ore dumps and waste from old uranium production facilities. Furthermore, REMs have been detected in coal ash deposits located in the vicinity of thermal power plants. What, then, is the problem?

The issue arises from the rarity of these elements being found in concentrated form. With regard to the processing of waste, the maximum amount of material that can be used is 70 grams per kilogram of raw material. However, this is an exceptional occurrence. A rate of half a gram per kilogram is standard. However, extracting these grams would require the construction of a large-scale production facility worth billions of dollars. It is imperative that these facilities are equipped with robust environmental protection measures, given the typically harmful nature of the leaching method employed for extraction.

However, let us consider a scenario in which billions are invested. What was the outcome? China Northern Rare Earth Group, the world's leading producer of rare earth metals, has reported a profit of just $215 million for the first nine months of last year. This indicates that its annual net profit could be less than $300 million. This is particularly noteworthy in a year marked by a surge in the prices of rare earth metals, driven by significant market interest. The production of these elements is not a major business, since humanity requires only a small amount of them.

In this context, we are confronted with the conceptions known as "market economics" and "capitalism," to which a significant proportion of the global population still adheres. If it is not possible to generate significant revenue from rare earth metals in a timely manner, then it would be unadvisable to expend resources on this endeavour. The game does not meet the required standards.

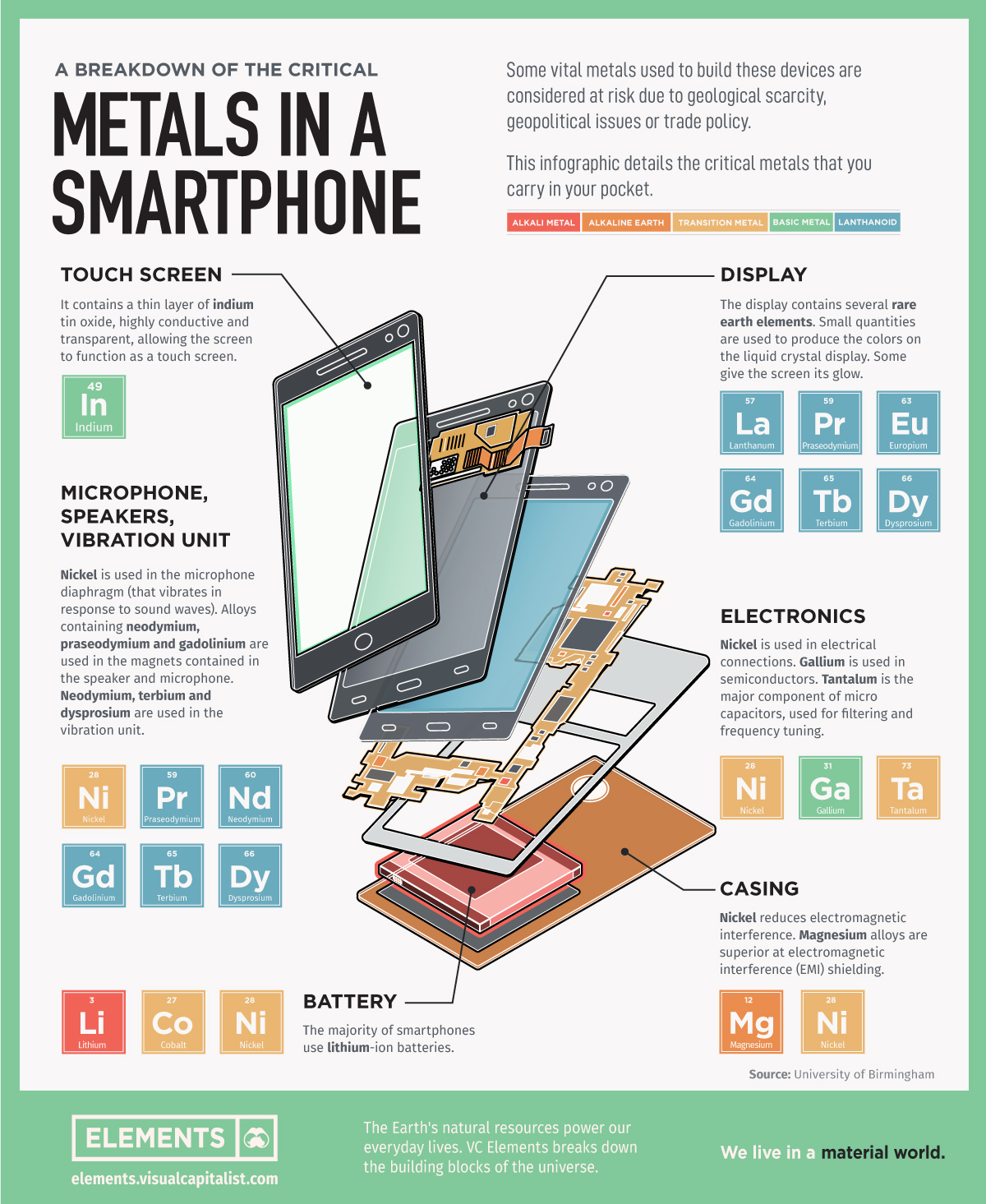

However, it should be noted that the production of most electronic devices is dependent on the availability of rare earth metals. It is not possible to produce permanent magnets for electric motors in the absence of these components. In the absence of these components, the smartphone screen will be unable to transmit data regarding the user's finger touch. The laptop monitor is not displaying anything. It is important to note that a laser cannot transmit signals through fibre optics, and as a result, the internet would be compromised. Chemists will not develop catalysts. It is important to note that, for Donald Trump, the manufacture of rocket engines and radars will not be a priority.

In summary, the construction of facilities for the production of rare-earth metals is not a viable business proposition within a capitalist system. In this case, the conventional free market principles that are typically invoked are rendered largely ineffectual. It is highly likely that the profits reported by Chinese manufacturers for 2025 are fictitious. The Chinese government has a long-standing practice of providing significant subsidies to critical industries, a strategy that has yielded notable benefits over the years. If government interventions, both overt and covert, are taken into account, it becomes evident that these plants are operating at a significant loss and will require external support to reach break-even point. However, if we consider the entire chain, it becomes apparent that a bottleneck must be overcome. The loss of such "non-essential" enterprises would result in a significant setback for humanity, as we would forgo the development of vital technologies.

During the period of competition between the US and the USSR, the price of rare earth metals was not a consideration. It was a matter of physical survival. In the face of this challenge, both sides were compelled to develop extraction technologies, however inefficient and environmentally harmful they might be, in order to ensure their competitiveness in the future. When one of the adversaries surrendered, the other relaxed. The company has relocated its microelectronics production to Taiwan, with a view to optimising its production processes and achieving cost efficiencies. Consequently, Taiwan no longer requires rare earth metals. In instances where the military-industrial complex required certain resources, China was a reliable source of supply.

Experts indicate that work to restore rare earth metal mining technologies in the United States is currently underway. If necessary, they will find waste dumps on their own territory, although the Greenland sand is likely to be more lucrative.

Russia formally acknowledged the issue in 2014. For instance, Rosatom has achieved considerable success in the development of rare earth elements. While the numbers are not yet fully clear, it appears that the rare earth problem in Russia is not as severe as it is in the US.

It should be noted that REEs are not the only example of a bottleneck. Please find below another example. If we consider the production process for both nuclear warheads and fuel assemblies for nuclear power plants, we find that uranium enrichment is a key step, located approximately midway through the process, closer to the beginning. It is important to note that the proportion of uranium-235, the isotope that actually participates in nuclear reactions, in the ore is only 0.7%. The remaining 99.3% is uranium-238. In the context of nuclear power plants, it is imperative to increase the proportion of uranium-235 to 5% in the "pellets" that are utilised. For a bomb, this must be increased to 80%. Prior to the dissolution of the Soviet Union, the United States utilised membrane enrichment technology. Firstly, they obtained uranium hexafluoride gas. The substance was then passed through a substantial cascade of ceramic filters – 4,000 of which were contained within a multi-kilometre pipe. Uranium-235 demonstrated a slightly higher level of permeability through pores measuring ten nanometres when compared with uranium-238. This was the method by which they were separated. In the USSR, cascades of centrifuges were used for the same purpose, exploiting the difference in masses of the two isotopes.

Following the dissolution of the Soviet Union, it was revealed that centrifuge technology was at least four times more cost-effective than membrane technology in terms of production costs. Membrane enrichment plants have been closed. The United States currently does not enrich uranium independently. This means that they are essentially unable to manufacture fuel assemblies for their nuclear power plants, or even build a nuclear bomb. The company's supply chain is reliant on outdated stockpiles of radioactive materials, in addition to supplies sourced from international markets. For instance, Russia ceased its exports to the United States two years ago.

It should be noted that there is some degree of exaggeration in this. In the US, there is a centrifuge enrichment plant called URENCO in New Mexico. The technology in question was originally developed by German scientist Gernot Zippe in the USSR. He was a prisoner of war, working in a "sharashka" (a "sharashka") alongside his Soviet colleagues. In 1956, Zippe was released to West Germany, where he assembled his own centrifuge, which was partially different from the Soviet one. URENCO, the current proprietor of the technology and its primary custodian, is not a US company. It is a joint venture between the governments of the UK and the Netherlands and two German corporations, E.ON and RWE. URENCO does not manufacture centrifuges in the US. The company imports the equipment to its US facility ready-made. In light of the deteriorating relations with the EU, will the US be able to obtain even a single new batch of this equipment? An excellent point. Despite numerous attempts, they have been unable to produce their own centrifuges.

These examples clearly demonstrate the inefficiencies inherent in the market and capitalist economic systems. The threat they pose to countries if one remains a devout supporter of these economic systems is significant. The Chinese government does not consider the "return on investment" when making such decisions. It is evident that such considerations are not a primary focus in this environment. It is precisely for this reason that China has become the leading monopoly in this sector. It is now seeking to coerce the US by restricting its supply of rare earth metals. Until such time as technology and production are restored, the US will be unable to mass-produce sophisticated weapons against China or develop microelectronics. This is largely due to the company's historical focus on accounting, which has led to a concentration of resources in this area. Management was too effective.

With regard to the extensive documentation required for rare earth metal mining that Trump continues to sign with various countries... This is not related to the supply of rare earth metals. Such an agreement is a symbolic act. By signing such a contract, individuals are effectively conveying their loyalty to the United States, both to President Trump and to the global community. The importance of rare earth metals has been called into question.